- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

CZ-126A/CZ-126B

White powder

| Availability: | |

|---|---|

| Quantity: | |

Performance characteristics

1. Non-toxic and environmentally friendly, can completely replace lead-based and organic tin-based stabilizers,

2. Excellent thermal stability and initial colorability, no vulcanization pollution;

3. Endow the product with excellent color brightness and color fastness;

4. Endows the product with excellent adhesiveness and printing performance.

Technical parameter

Appearance: white or light yellow powder

Recommended dosage (servings) 3.0~4.5

Model No. | Appearance | Heating Loss (90±2℃) | Initial Melting Point |

CZ-126A | High-end type, good thermal stability and processability, suitable for thick edge edge banding | <5% | ﹥105℃ |

CZ-126B | Standard type, good stability and initial color, suitable for thin edge edge banding | <5% | ﹥105℃ |

Safety performance:

It is a non-toxic substance, and the products comply with the EU RoHS directive, EN71-3, PAHs polycyclic aromatic hydrocarbons (18 items), PFOS/PFOA, REACH-SVHC and other environmental protection standards;

Packaging and storage:

Composite paper bag 25kg/bag, dry storage, avoid rain, sealed and stored.

|  |

|

|  |

There are many benefits to using a calcium zinc stabilizer for PVC edge seals. This type of stabilizer provides superior resistance to UV radiation, weathering, and abrasion. It also offers excellent color stability and does not promote crazing or yellowing of the PVC. In addition, the use of a calcium zinc stabilizer can extend the life of the PVC seal by up to three times compared to seals made with other types of stabilizers.

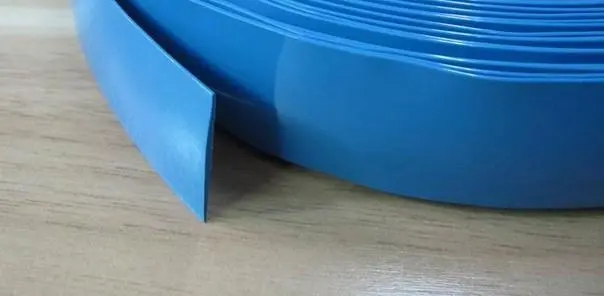

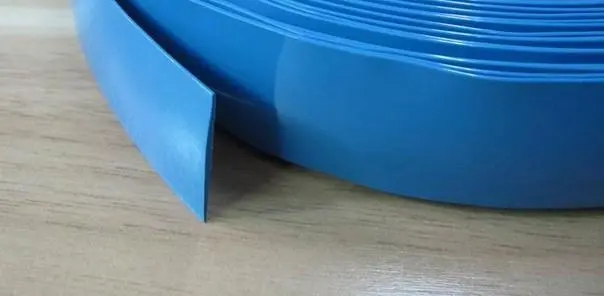

PVC edge seals are used to protect the edges of PVC products from damage. They are made from a variety of materials, including calcium carbonate, zinc oxide, and titanium dioxide.

Calcium carbonate is the most popular material for PVC edge seals. It is inexpensive and has a high melting point, making it ideal for use in high-temperature applications. Zinc oxide is another popular choice for PVC edge seals. It is more expensive than calcium carbonate but has a lower melting point, making it suitable for use in low-temperature applications. Titanium dioxide is the most expensive option for PVC edge seals but has the highest melting point of all three materials.

There are a number of technical parameters that need to be considered when selecting a calcium zinc stabilizer for PVC edge seals. The most important parameters are the thickness of the seal, the Shore hardness, and the open time.

The thickness of the seal is an important parameter because it determines how strong the bond between the two pieces of PVC will be. A thicker seal will have a stronger bond, but it will also be more difficult to apply. The shore hardness is another important parameter because it determines how hard or soft the PVC edge seal will be. A harder seal will be more resistant to wear and tear, but it will also be more difficult to apply. The open time is the amount of time that the glue has to set before it dries and becomes unusable. A longer open time will give you more time to work with the glue, but it can also cause problems if you don't allow enough time for it to dry properly.

PVC edge seals are an important component in many construction applications. They provide a water-tight seal between two pieces of PVC pipe, and can also be used to seal the edges of concrete and metal pipes. CALCIUM zINC sTABILIZER is a new product that is designed to stabilize PVC edge seals, making them more durable and reliable.

CALCIUM zINC sTABILIZER is a water-based solution that is applied to the surface of PVC edge seals. It penetrates into the seal and bonds with the PVC, creating a stronger bond than traditional methods. This new product is ideal for use in harsh environments, where traditional edge seals may fail due to weathering or chemical attack.

CALCIUM zINC sTABILIZER has been tested in a variety of climates and conditions, and has proven to be an effective stabilizer for PVC edge seals. In addition to its durability, CALCIUM zINC sTABILIZER also provides superior UV resistance, making it an ideal choice for outdoor applications.

Performance characteristics

1. Non-toxic and environmentally friendly, can completely replace lead-based and organic tin-based stabilizers,

2. Excellent thermal stability and initial colorability, no vulcanization pollution;

3. Endow the product with excellent color brightness and color fastness;

4. Endows the product with excellent adhesiveness and printing performance.

Technical parameter

Appearance: white or light yellow powder

Recommended dosage (servings) 3.0~4.5

Model No. | Appearance | Heating Loss (90±2℃) | Initial Melting Point |

CZ-126A | High-end type, good thermal stability and processability, suitable for thick edge edge banding | <5% | ﹥105℃ |

CZ-126B | Standard type, good stability and initial color, suitable for thin edge edge banding | <5% | ﹥105℃ |

Safety performance:

It is a non-toxic substance, and the products comply with the EU RoHS directive, EN71-3, PAHs polycyclic aromatic hydrocarbons (18 items), PFOS/PFOA, REACH-SVHC and other environmental protection standards;

Packaging and storage:

Composite paper bag 25kg/bag, dry storage, avoid rain, sealed and stored.

|  |

|

|  |

There are many benefits to using a calcium zinc stabilizer for PVC edge seals. This type of stabilizer provides superior resistance to UV radiation, weathering, and abrasion. It also offers excellent color stability and does not promote crazing or yellowing of the PVC. In addition, the use of a calcium zinc stabilizer can extend the life of the PVC seal by up to three times compared to seals made with other types of stabilizers.

PVC edge seals are used to protect the edges of PVC products from damage. They are made from a variety of materials, including calcium carbonate, zinc oxide, and titanium dioxide.

Calcium carbonate is the most popular material for PVC edge seals. It is inexpensive and has a high melting point, making it ideal for use in high-temperature applications. Zinc oxide is another popular choice for PVC edge seals. It is more expensive than calcium carbonate but has a lower melting point, making it suitable for use in low-temperature applications. Titanium dioxide is the most expensive option for PVC edge seals but has the highest melting point of all three materials.

There are a number of technical parameters that need to be considered when selecting a calcium zinc stabilizer for PVC edge seals. The most important parameters are the thickness of the seal, the Shore hardness, and the open time.

The thickness of the seal is an important parameter because it determines how strong the bond between the two pieces of PVC will be. A thicker seal will have a stronger bond, but it will also be more difficult to apply. The shore hardness is another important parameter because it determines how hard or soft the PVC edge seal will be. A harder seal will be more resistant to wear and tear, but it will also be more difficult to apply. The open time is the amount of time that the glue has to set before it dries and becomes unusable. A longer open time will give you more time to work with the glue, but it can also cause problems if you don't allow enough time for it to dry properly.

PVC edge seals are an important component in many construction applications. They provide a water-tight seal between two pieces of PVC pipe, and can also be used to seal the edges of concrete and metal pipes. CALCIUM zINC sTABILIZER is a new product that is designed to stabilize PVC edge seals, making them more durable and reliable.

CALCIUM zINC sTABILIZER is a water-based solution that is applied to the surface of PVC edge seals. It penetrates into the seal and bonds with the PVC, creating a stronger bond than traditional methods. This new product is ideal for use in harsh environments, where traditional edge seals may fail due to weathering or chemical attack.

CALCIUM zINC sTABILIZER has been tested in a variety of climates and conditions, and has proven to be an effective stabilizer for PVC edge seals. In addition to its durability, CALCIUM zINC sTABILIZER also provides superior UV resistance, making it an ideal choice for outdoor applications.